Premier Plasma Dross Reduction Guide During Cutting

Dross or slag is your Enemy!

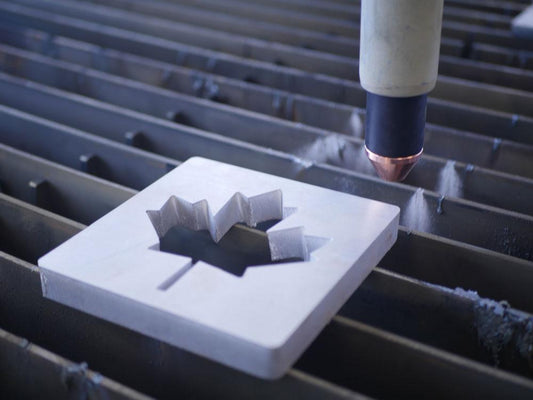

dross or slag refers to the existence of unwanted cutting matter at the bottom of the cutting area resulting from molten metal during the cut, the word splatter is another name for your enemy!

excessive buildup of hardened metal on your cut, will lead to costly downtime due to the needed post-cut cleaning Operation.

Dross, Shape and solution:

top of the workpiece:

if the dross or spatter starts building up on the top of the workpiece, this is usually cause by bad consumables (usually bad cutting tip).

if the cutting speed is too high, the plasma arc will not be able to fully penetrate the workpiece, causing dross to buildup on the top of it too.

also, having the torch cut height set too high (standoff), will also start building up dross on top of the workpiece.

Solution:

* Check your cutting tip (especially if it appears to be worn).

* Slightly decrease your cutting height until you to minimize dross.

* Lower your plasma amperage until you find a compromise between plasma amps and speed for the specific steel thickness.

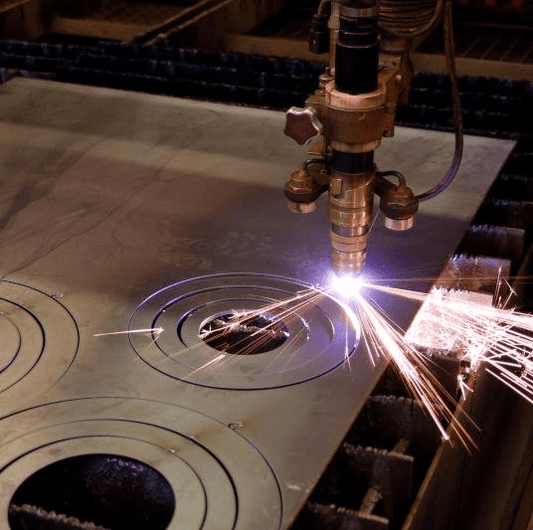

Dross appearing at high speeds

at higher speeds, the plasma cutting arc will start to through behind the torch due to excessive cutting speed. as the below image implies, the torch will need to be slowed down, in order to give the arc more chance to fully penetrate the cutting path.

Solution:

* Again, it could be your cutting tip.

* Adjust your cutting speed slowly down, especially for thicker material.

* Lower your torch cutting height.

Still Getting Dross even at lower speeds?

even when you are cutting too slow, the plasma arc will start melting more metal from the sides of cutting path to keep the arc running!

the kerf width will become wider, until it reaches a point where the blown gas velocity can no longer blast the molten metal away, resulting in thicker heavier layer of slag under the cutting path!

Solution:

* Adjust your cutting speed slightly up.

* Adjust your torch Cutting height.

* Reduce your plasma cutting amperage.