Premier Plasma CNC: Unveiling the Dynamics of CNC Plasma Tables

In the world of metal fabrication, CNC plasma tables have revolutionized the cutting process, offering unparalleled precision and efficiency. This blog post explores the remarkable world of CNC plasma tables, focusing on Premier Plasma CNC and its cutting-edge solutions. Let's delve into the fascinating realm of Premier Plasma CNC and discover how these tables work their magic.

Understanding CNC Plasma Tables

CNC plasma tables are sophisticated computer-controlled cutting systems that utilize plasma technology to carve through various metals with unparalleled precision and incredible speed. Premier Plasma CNC is a leading provider in this field, offering cutting-edge tables that transform the metal fabrication process. These tables are engineered to handle a wide range of materials, from stainless steel to aluminum, making them versatile and adaptable for different cutting needs.

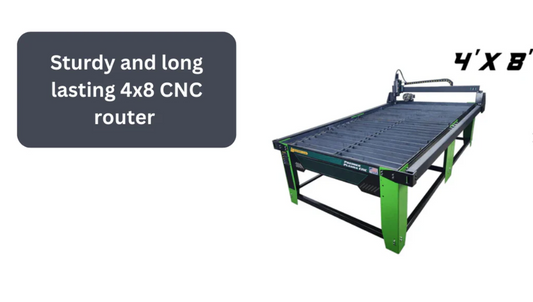

Components of a Premier Plasma CNC Table

Premier Plasma CNC tables are crafted with precision-engineered components to ensure the utmost performance and durability. These components include a robust cutting torch, a sturdy cutting bed with advanced slat systems to support the metal, a powerful control system with user-friendly software, and a precise gantry system equipped with high-quality motion control mechanisms. Premier Plasma CNC tables are designed to deliver exceptional reliability and accuracy.

Working Principles of Premier Plasma CNC Tables

The operational principle of Premier Plasma CNC tables revolves around the concept of plasma cutting. This cutting-edge process employs a concentrated stream of ionized gas to heat and melt the metal, enabling precise and clean cuts. Premier Plasma CNC tables simplify operation through their intuitive control system software, allowing operators to import design files and execute cutting instructions. The control system coordinates with the gantry system, guiding the cutting torch along the programmed path and ensuring precise execution of the cutting process.

Advantages of Premier Plasma CNC Tables

Premier Plasma CNC tables offer an array of advantages and benefits. These tables deliver incredible precision, minimizing material waste and reducing the need for additional processing. The speed and efficiency of Premier Plasma CNC tables enable faster project completion compared to manual cutting methods, optimizing productivity. These tables excel in versatility, effortlessly handling intricate designs and complex geometries. Premier Plasma CNC tables can also be customized to cater to specific cutting requirements, making them adaptable to diverse applications.

Elevating Your Metal Fabrication with Premier Plasma CNC

Premier Plasma CNC tables empower businesses across a wide range of industries, including automotive, aerospace, and construction. These tables excel in cutting various components for architectural designs, bespoke metal art, signage, and structural elements. By incorporating Premier Plasma CNC tables into their operations, fabricators experience increased productivity, enhanced precision, and exceptional results, setting their businesses apart from the competition.

Premier Plasma CNC tables are at the forefront of CNC plasma cutting technology, offering remarkable precision, efficiency, and versatility. By investing in Premier Plasma CNC, fabricators can unlock new possibilities, enhance productivity significantly, and achieve outstanding results. Delve into the extraordinary world of Premier Plasma CNC and experience the transformative power of these state-of-the-art CNC plasma tables.