Tips to Choose a Light Industrial CNC Plasma Table

Tips to Choose a Light Industrial CNC Plasma Table

Whether you are a hobbyist or working at a professional level in the CNC business, you must maintain a balance of quality and affordability. Bills can quickly pile up if you purchase equipment recklessly.

This scenario is especially true for CNC plasma tables since they can get crazily expensive. These machines help you accomplish several projects and deliver premium-quality results; however, you must keep specific parameters in mind before finalizing one.

Tips to Choose a Light Industrial CNC Plasma Table

Here are some practical tips that can help you pick a light industrial CNC plasma table that satisfies your needs and yields a decent ROI -

1. Seamless Usage and Maintenance

A light industrial CNC plasma should be easily operable and should not require professional supervision every time it gets used. It should be easy to maintain and demand minimal maintenance and upkeep. The plasma table should deliver peak performance whenever needed, irrespective of workload.

It should not show signs of wear or a plummet in product finishing even when operated for over eight hours a day for seven days a week. Besides being low on maintenance, your preferred plasma table should get assembled easily and be fully functional within minutes of arrival.

If you require extra features, look for a CNC plasma table with a user-friendly controller, built-in at-machine CAD/CAM capabilities, and an onboard diagnosis system.

2. High Precision Levels

One of the biggest giveaways of high-quality CNC equipment is their unrivaled precision. Your preferred choice of plasma table must be high on accuracy levels, such as precision milling of contact surfaces to ensure bearing and rail placement.

Your preferred CNC plasma table's frame must feature higher tolerance levels than the competition to deliver high precision and accuracy. CNC plasma tables that use frames with high tolerances are also easy to maintain and less power-hungry.

Small businesses can opt for a desktop CNC machine to obtain high precision while staying within budget. These machines can perform different tasks and are not as power-hungry as the big ones.

3. Plasma Types and Power Levels

The common types of plasma cutters are air plasma systems since they are the most cost-effective option when looking for an entry-level CNC table. Ensure that the plasma you purchase comes with a blowback start and not a high-frequency one since it hinders the PC-based machine control and onboard electronics.

It is also crucial to determine the thickness of the metal you intend to cut and the total cutting required.

Besides plasma types, you must also look out for their power levels. Most plasma systems in the market come with a 50% duty cycle. If you wish to cut for long hours, invest in a system that is rated higher than the thickness you intend to cut. This gesture ensures that the system does not overwork itself and lets you cut for long hours.

It is also advisable to check out the available torch options in the market. While some table manufacturers create designs that facilitate mounting and cutting using a hand torch, it is not recommended since it is relatively easier to mount and square a machine torch to the plate.

4. Miscellaneous Influential Factors

Here are some other factors that you must consider when purchasing a light industrial CNC plasma table -

- CAD/CAM software

Some plasma tables do not offer CAD drawing software, post-processor, or CAM software on their purchase. CAM software is crucial since it accepts the drawing file from CAD and transforms it into machine code.

Evaluate the software package options offered by different table manufacturers before finalizing a choice. This is because the learning curve and time consumed to learn it differs significantly across the software.

Some CNC table providers also offer subscriptions, along with training, automatic software updates, and technical support, often for an extra charge.

- Torch Height Control

Some plasma tables do not offer a torch height control, which reduces the overall cost of the setup. However, height control is crucial and a non-negotiable since it is vital to edge angularity and the table's longevity.

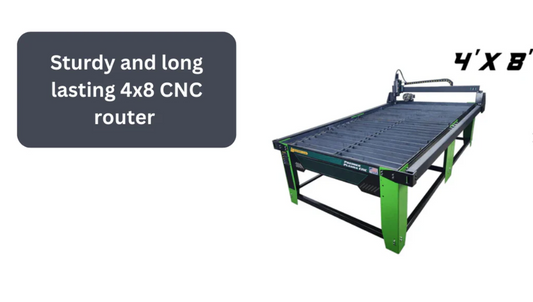

- Table size

Most entry-level CNC plasma tables have cutting bed dimensions as 4′ x 4′, 4′ x 8′, and 5′ x 10′. You also have the option to purchase a 2′ x 2′ CNC plasma table if you are on a tight budget. However, such a small size limits your options, and you cannot find steel plates narrow enough that fit a 2′ x 2′ table.

5. Cost-Effectiveness

If you are venturing into the world of CNC as a hobby, you will soon realize that it is a tedious job to find relevant equipment at an affordable price. While most brands manage to deliver highly usable and precise CNC plasma tables, they often cost a fortune.

However, certain brands offer industrial capabilities while charging for an entry-level CNC plasma table. These brands deliver technology that would typically amount to $60,000 for as low as $13,000.

Look for companies that offer flexible payment options and financing so that you don't struggle with paying a lump-sum amount. After going through this guide, you should pen down the features you want and set a budget accordingly.

Final Words

Light industrial CNC plasma tables deliver high precision, greater efficiency, and extreme versatility. Hobbyists and full-time commercial shop owners use these machines to produce remarkable results. However, when in the market looking to purchase one, there are certain factors that you must account for, as mentioned above. Besides that, you must stay within budget since these machines can go exceedingly high in the price range.

About the Author:

Peter Jacobs

Peter Jacobs is the Senior Director of Marketing at CNC Masters. He is actively involved in manufacturing processes and regularly contributes his insights for various blogs in CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in general.