How to Choose the Best CNC Plasma Cutter Machine for Your Workshop

Investing in a CNC Plasma Cutter Machine is an important decision for any metalworking shop. Simply adding this machine to a workshop can see an impressive increase in productivity and efficiency. It is safe and accurate and allows manufacturers to create complex designs and shapes with ease.

However, precision and accuracy vary depending on the type of CNC machine you choose. So it's normal to have a lot of questions about the factors that should be considered before buying a CNC machine. Hence, we've compiled those factors to help you choose the right CNC machine for your business. Let's take a look at them.

Factors to Consider When Choosing a CNC Plasma Cutter Machine

1. Understand Your Needs

The first and foremost factor to consider is your needs. So, ask yourself these questions that -

- What materials will you be cutting? Since, most CNC plasma cutters are designed to cut various metals including steel, aluminum, copper, and more.

- What thickness do you need to cut? Determine the metal’s thickness that you will most frequently cut. So that the plasma cutter you choose can handle the maximum thickness of the materials you’ll be working with.

- What is your budget? It is important to have a budget in mind because the prices of CNC plasma cutters vary.

2. Consider the Cutting Speed

Cutting speed is a vital aspect that affects productivity. A faster cutting speed can save time and increase efficiency, which is quite excellent when you have so many projects. Ensure that the seller should provide you with cutting speeds for all metal thicknesses measured in IPM (inches per minute).

However, check that the machine maintains precision and quality at higher speeds. For example, to perform long, fast, quality cuts on ¼" steel, choose a 1/2" class (60 amp) CNC plasma cutter machine.

3. Evaluate the Power Source

CNC plasma cutter machines come with different voltage capacities. This mostly ranges from 110V to 240V. So, when you go to buy, check that the CNC machine matches the power supply of your workshop. Also, you can think about the amperage as high amperage means the ability to cut thicker materials.

4. Software and Control Features

Advanced CNC plasma cutters come with software and control features. These features help in improving precision and ease of use. So, look for the following features:

- CAD/CAM software: This enables you to design and plan your cuts with precision.

- User-friendly interface: This simplifies operation to reduce the learning curve.

- Automatic torch height control: This maintains consistent cutting quality.

5. Safety Features

Look for a CNC machine that has a Nozzle-in-place safety sensor and pre-flow sequence feature. The nozzle-in-place sensor does not allow an arc to start until the nozzle is in place. And, the pre-flow sequence gives an advanced warning of the arc initiation before use.

Moreover, some basic safety features are crucial for every CNC plasma cutter machine to have - Automatic shut-off (prevents overheating and potential accidents), protective covers (protects the operator from sparks and debris), and ergonomic design (reduces operator tiredness and injury risk).

6. Find the Portability Factor

Many manufacturers need to move the machine around a job site, plant, or even from site to site. So, in such a situation lightweight and compact models are good to easily transport and store. Also, if your workspace is limited, go for a machine with a small footprint.

7. Easy Operation

Test the machine yourself and check its cutting quality. So, that you know how easily it works and feels comfortable.

CNC plasma cutter machines with a big, easy-to-read control panel are more user-friendly. Such a panel allows people to use machines easily who don't normally use plasma cutters. Also, procedural information printed on machines helps users in case of set-up and troubleshooting.

8. Ask for Recommendations

The last factor, but you know it's very important. So, before making an informed decision, ask for recommendations from peers in the industry. As you know, feedback from people who use it daily or frequently can give you honest insights on the performance and reliability of the plasma cutter you are thinking of buying.

Conclusion

All the best. We hope you have a list of 7 factors to consider when buying a CNC plasma cutting machine. As a CNC machine can significantly impact the productivity and efficiency of metal-cutting projects, you must make this decision carefully. Just note down these factors on a note and make sure you check all these boxes.

Well, you don't have to find every aspect according to you, but at least buy a CNC plasma cutting machine that enhances productivity and safety. So that you can serve your workshop’s needs for years to come.

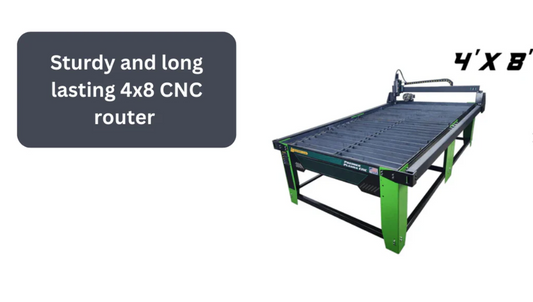

Ready to upgrade your workshop with a top-notch CNC plasma cutter? Visit Premier Plasma, an online shop for CNC Machines with 2000+ happy customers. With excellent customer service and a commitment to quality, Premier Plasma is your go-to destination for all your CNC plasma cutting needs. Take your workshop to the next level!

Learn the mistakes to avoid before buying CNC Machines.