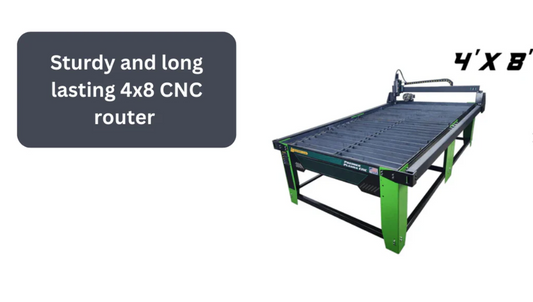

Top 10 Benefits of a CNC Plasma Cutting Machine

Did you know the success of industrial construction, shipyard manufacturing, metalworking, and fabrication mostly depends on efficiency and precision? This is eventually possible with high-quality equipment. No doubt you may be an expert in your field, but you will still need modern technology to give your best. This is where CNC Plasma Cutting Machines play an important role (Computer Numerical Control).

These CNC machines feature a plasma cutter used to cut metals. It is programmed and controlled by a computer rather than manually operated.

10 Benefits of CNC Plasma Cutting Machine

As plasma cutting is a significant task in completing many projects, let’s clearly understand the reasons why CNC plasma cutters are significant in boosting efficiency and precision:

1. Precision Cuts

If you have never used a CNC plasma cutter, then let us tell you that these are machines that cut metal like butter glides on bread.

They cut steel, aluminum, and even copper with full accuracy and perfection. Because CNC cutting machines use torches that are controlled by a computer.

2. Speedy Production

CNC plasma cutting machines prove that time is money because they work fast and save time. They smoothly cut materials in less time compared to traditional methods so that you can perform other tasks.

You know that CNC plasma cutters need only a quarter of the time to perform tasks in comparison to other tools. They don't need to be preheated before use. Ultimately, CNC plasma cutting machines play an important role in completing the project on time.

3. Versatility

CNC cutting machines can handle various shapes, sizes, and materials, such as - steel, iron, copper, brass, aluminum, stainless steel, and other materials. Plasma cutting is the fastest cutting method. They can even cut different materials stacked on top of one another.

Whether you need complex designs or simple cuts, CNC plasma cutting machines are the only machines you need. CNC plasma cutter is an important tool in multiple projects, like fabrication, shipyard manufacturing, construction sites, metalworking, maintenance & repair, and trade schools.

4. Cost-Effectiveness

CNC plasma cutting machines can be expensive. But what you may not know is that they ultimately reduce the cost of production. You can ask how. By using CNC plasma cutters, you can cut metals faster with minimal material waste, reduced labor cost, and maximum efficiency.

Ultimately, CNC plasma cutting machines reduce the price for the end customer and benefit you in the long run.

5. Increased Productivity

CNC plasma cutting machines have automatic torch height control and sophisticated CAD & CAM cutting software. So you can be more productive and cut more in a day with less wastage.

Humans can make mistakes, but machines rarely do. CNC plasma cutters give the precise cut and shape you want. So that you do not have to rework and save time & effort. This ensures happy customers in the end, eventually customer retention.

6. Complex Designs Made Easy

If you are new to using CNC plasma cutting machines, then don't worry. CNC plasma cutters have accurate controls and software features. You can easily cut complex designs. Now, you are ready to tackle complex patterns and shapes without expertise.

7. Minimal Setup Time

Again, CNC plasma cutting machines prove that time is money.

We all know that time is an important factor in the manufacturing world. Hence, CNC cutting machines require minimal setup time. So that you just come to the workplace and start working quickly without wasting minutes.

8. Scalability

CNC plasma cutting machines are great for small businesses as well as large-scale manufacturers. They can easily scale to meet your needs. CNC plasma cutters can handle the increased workload without being tired as they’re machines, not humans.

9. Safety

Safety is an important measure in any workplace, and CNC plasma cutting machines prove it. It has amazing features like automatic shutdown; it automatically gets shut down when any emergencies and enclosed cutting areas. So, it is clear that CNC cutting machines ensure a safe working environment for operators.

10. Easy to Use

One of the best benefits, i.e., easy to use.

In ancient times, there were machines that required proper training to use them. However, when it comes to CNC plasma cutting machines, they are easy to use and require minimal training. So the time and cost spent in training those workers reduces eventually. In such a way, one-man shops can even buy CNC plasma cutters to use effectively.

Final Thoughts

Well, it's not the end yet. While using CNC plasma cutting machines, you may find some other reasons why these machines are more beneficial. Their benefits are undeniable for manufacturers.

From precision cuts to cost-effectiveness, versatility to safety, CNC plasma cutting machines are just wonderful for manufacturers.

So why wait? We know you’re an expert so unlock your full potential with CNC plasma cutting machines.

(Embed here this link: https://premierplasmacnc.com/blogs/news/plasma-cutting-safety-guide )