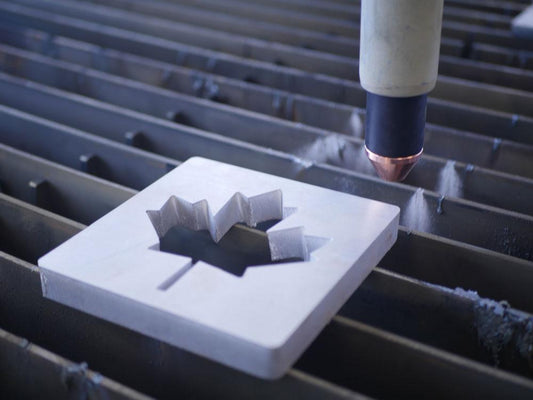

All About The THC (Torch Height Controller)

* Note: The model we use on our tables, and we explain here is: Proma SD Compact THC.

Safety Note!

WHEN THE DEVICE IS IN OPERATION, VOLTAGE HAZARDOUS TO HEALTH AND HUMAN LIFE IS PRESENT INSIDE THE HOUSING AND AT THE CONNECTION TERMINALS

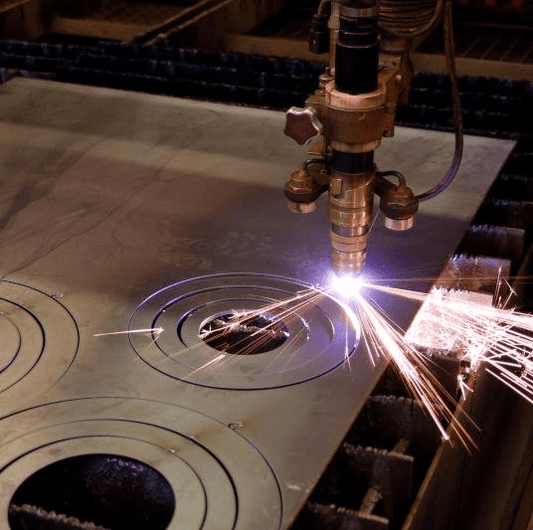

Warning: Provide adequate protection for all risks associated with plasma cutting.

For more detailed information of the risk associated with plasma cutting, refer to your plasma cutter's owner manual.

If you have any questions or are unsure about anything stated in this manual problem, immediately contact Premier Plasma CNC Tech Support line (602 899 1115) for assistance.

What is the THC ?

The THC is a modern analogue - microprocessor plasma torch height controller that operates by analyzing voltage changes in the plasma source due to variations in height between the torch tip and the material being cut. The microprocessor makes determinations to raise or lower the torch based off of the strength of the voltage signal being read. It is equipped with an easy to read LED display and two user friendly keys making operation simple and does not require any additional measuring instruments. The device has patented solutions made with the highest quality components to ensure a safe, durable, and reliable long-term operation.

Simplified block diagram:

Pilot Arc Voltage Neutraliser - protection system, which is responsible for removing spikes in the AC electrical flow, which can be caused by a plasma source with contact-less arc striking (HV/HF pilot arc) generating a high voltage or from surges coming from plasma cutters equipped with contact arc striking system.

Main Arc Voltage Divider – While in operation, the cutter generates dangerous voltage levels, unsafe for precision electronics. A voltage divider system is incorporated to reduce this voltage to a safe level.

A quick acting filter system removes any interference that may pass through a voltage divider.

Filtered and scaled voltage values derived from the plasma cutter's “raw arc voltage” are then sent to the brain of the device. The "brain" consists of a programmed microprocessor, which in addition to the analysis of the cutting voltage parameters and proper output blocks controlling, also supports the LED display and function keys.

Proma SD THC Wiring

When connecting directly, use the shortest possible cables for connecting the plasma source with THC controller - it is recommended the THC controller to be located directly at the plasma source.

While being a universal THC, accepting full raw arc voltage for most any plasma cutter on the market, an exciting new standard feature of this unit is the addition of a 1:50 divider for an extremely fast, simple installation on most major brands. There will most likely be a direct connection for this on the outside of the plasma cutter's unit. Please refer to your plasma cutter owner's manual.

Hypertherm powermax x45 Connection

An example of how to connect the THC controller's measurement input with the output of the very popular Hypertherm Powermax45 ® - The THC comes standard equipped with a low voltage output of 1:50 divider. This ratio is the most commonly used division in most major brands and there will most likely be a plug for this connection on the outside of the cutter's unit.

Description of relay outputs:

The relay outputs “Arc, Up, Down”, are controlling outputs via relays, and should not be utilized for anything other then it's intended use.

COM terminal is a common input terminal connected to the ARC, UP and DOWN relay contacts inside the device, according to the diagram located on the cover (above picture). Suggested route is to “GND” at driver/pc end. Do not jumper this connection to the “7-35V” negative.

ARC output (also known as “Arc Okay”) is activated when plasma ignition is detected. Route and configure for a software input. Not required to operate. 5

UP output is activated when the measured voltage is lower than the voltage setpoints, reduced by half the hysteresis voltage. Route and configure for a software input.

DOWN output is activated when the measured voltage is higher than the voltage setpoints, reduced by half the hysteresis voltage. Route and configure for a software input.

Note: No output relays are activated in case when only the pilot arc is detected and when the main arc is broken.

Relay outputs should be connected to the CNC system in accordance with the documentation of the CNC electronic system controlling the machine. For this, we use inputs of outermost connectors HOME or LIMIT - THC relay contacts should be connected to the terminals the same way as limit switches connectors. At the same time, the common COM terminal relay should be connected to the CNC system to a common terminal for limit switches (it is usually a GND terminal).

Start-up and operation

The device is pre-configured at the factory and after the correct connections are made, it immediately works properly with most plasma devices. After switching power on, the THC controller's display shows an "animated" "thc" message, and then a flashing voltage value is presented for 1 second; the device is undergoing automatic calibration at this moment.

In this state, by depressing both the up/down keys, simultaneously and holding for a few seconds, the voltage setpoints can be modified and thus set the torch's height above the material. Press shortly once to display the set value without modification. To determine other parameters simultaneously hold both keys until you see the desired parameter on the display - when you release the keys, its value will be displayed - using the up/down keys to set the desired value:

When the plasma cutter is switching on, the display presents the measured voltage value and LED diodes present the current status of outputs. Fast blinking of the measured value indicates the detection of pilot arc; continuous display indicates the detection of the main (cutting) arc. All parameters can be modified during operation; these changes are reflected in real time in the control of output signals.

THC Calibration

So the 1st 2 or 3 seconds you want to see what the THC is reading and then adjust as close as you can the to the voltage it was reading. Then a few volts up or down depending on the direction If the thc voltage is set to higher then around 12v off it will cause it to go the opposite direction an dive even though it seems like it should go up. You will also want to run no lead out this will help with it not diving.

Tutorial Video:

THC CONFIGURATION - YouTube

For what to set the thc to. Every Metal an thickness will read different voltages. For each metal thicknesses you cut its best to write down your voltage that the thc is set at. Between different thicknesses there will be a few volts difference up or down. You want your delay set a little bit higher than your delaying in sheetcam if you have no delaying in sheetcam then around .9 to 1.9 seconds delay on the thc.

Want to see the THC in Action?

Cutting corrugated material Premier Plasma CNC - YouTube

Cutting 14 Degree material. Premier Plasma CNC - YouTube

Want to purchase the Proma THC ? Check it out HERE!!