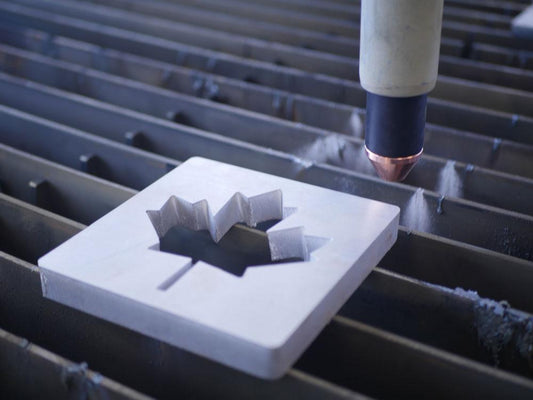

Cutting Stainless steel with your Premier Plasma CNC Table

.A common issue that people run into when trying to cut custom decorative parts or special parts.

in this Article, we will give a brief help to cutting Stainless steel in General and cutting on a Premier plasma CNC table specifically. let's start this article with the very frequent question.

Can you cut stainless steel with plasma machines?

YES! plasma cutting can be specified as the best cutting process for conductive materials, since plasma has the ability to cut a wide range of material thicknesses which makes it popular. plasma cutting is also very cost effective (has low captial and operational costs than other methods like water jet or laser cutting.

What is the expected Stainless steel cutting quality on a Premier Plasma CNC table?

as for most conductive material, we can expect a very precise and clean-cut quality out of plasma machines, depending on cutting settings and conditions.

plasma cutting quality is can also be dependent on the plasma cutter itself, depending on material thickness being cut. to be more specific, plasma cutting process, can produce parts that need minimal rework or no rework at all. this means, the end part will have smooth, sharp and shiny edges.

Factors Affecting stainless steel cutting Quality:

Many factors affect the cutting quality of metal, depending on cutting method, cutting settings and your plasma cutter. however, a good starting point would be the owner's manual because it contains a detailed cutting chart.

Stainless steel type:

Stainless steel is unique in that it is divided into families and grades that describe specific properties such as toughness, corrosion resistance, and composition.

There are four stainless steel families in all. For purposes of this article, we will only focus on the austenitic family as it is the most popular and widely used family thanks to its excellent weldability.

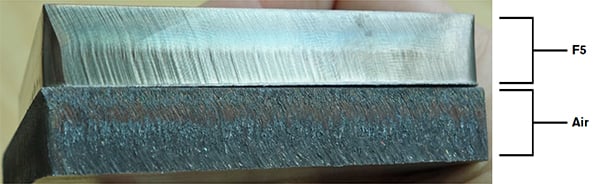

Right Gas selection:

Cutting Stainless steel is highly dependent on the type of gas you will use. You actually need two gases: a plasma gas – the gas that actually does the cutting – and a shield or secondary gas. the shielding gas, works as an overheating preventive. the most popular gases for plasma cutting regardless of material are:

- Air

- Nitrogen (would be best for stainless steel cutting).

- Oxygen

- H-35 which is a mixture of 35 percent hydrogen and 65 percent argon

- F5 which is a mixture of 5 percent hydrogen and 95 percent nitrogen

you have three potential gas choices when plasma cutting stainless steel: air, nitrogen, and F5. Using clean, dry air as your plasma and shield gas is the easiest, fastest, and most economical way to plasma cut stainless steel with an air plasma system.

(Image source: hypertherm website).