Beginners Guide to CNC Plasma Cutting

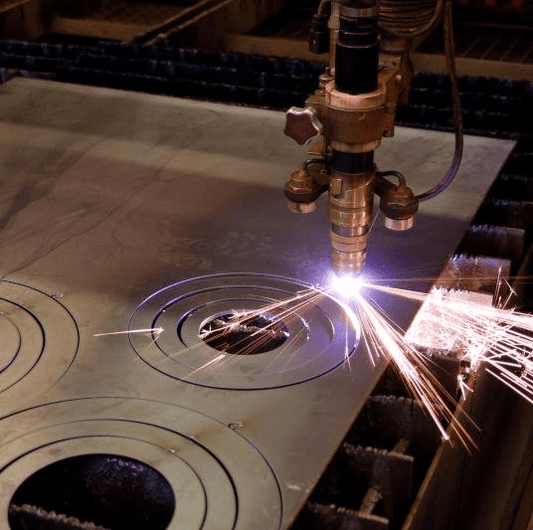

What is Plasma Cutting?

Plasma, as known to be the fourth state of matter, is a super-heated gas flow that is formed when compressed air or gas (like nitrogen or argon) make contact with the electrode (which is at the tip of the cutting torch) and ionise to create plasma.

plasma cutting, is a melting process that uses plasma and an outside power source to create an electric arc between the electrode and the metal being cut to melt and eject it from the cut.

Plasma Machine Setup:

1. Air/Gas Setup:

Unlike welding machines, plasma cutters are designed to work with compressed air only. fortunately an air compressor attaches to the back of a plasma cutter in the same way a gas tank connects to the back of a welding machine using an air regulator. an air compressor needs to be purchased separately from your local hardware store though.

The need for an air compressor limits down the portability of the plasma cutting machines. because you will always need to be connected to air supply and electricity.

when purchasing an air compressor, make sure it can supply air pressure in the range of 70 - 120 psi, and an air flow volume larger than the need of your plasma cutter.

2.Torch and consumables:

Plasma cutting is done in DCEN (Direct Current Electrode Negative). Getting the polarity correct on your plasma cutter is a lot easier than any form of welding because the plasma torches have a different shaped plug

Away from guesswork, your plasma cutting machines come with 2 ports, one for the torch and the other for ground clamp to complete the electric circuit. Make sure to attach your earth clamp to either a (clean) metal workbench or the part of the metal that will not fall away once it’s cut.

Standard Consumables Assembly:

Putting the consumables together to get your torch up and running isn’t too hard, and most machines will come with a guide either on the machine or in their User Manual.

- Electrode

- Swirl ring (gas distributor)

- Cutting tip

- Shield cap body (retaining cap)

- Shield cap

If you haven’t assembled the torch correctly, you’ll know about it straight away, as it won’t turn on. Most of these consumables will sit in place, so don’t try and twist or force things in; you’ll just end up breaking parts.

3.Settings

Amperage:

Unlike welding, the amps you set your machine to will not affect your cut all that much, so long as you adjust your travel speed to compensate. You can set your machine to its max amps and cut every thickness of metal, but if your machine goes up to 80A and you’re cutting 2mm steel, you’re going to have to fly across the cut to avoid warping or completely melting the metal.

Air Pressure

In general, the air pressure regulator can be found on the back of the machine above the air filter. The regulator will have a hose that runs in on one side and out on the other, with a twistable valve on top. This valve is how you change the air pressure, which you can see on the pressure gauge.

Most plasma machines come pre-set at a pressure level that will work well regardless of the amperage, and the regulator is inside the machine. A good starting pressure regardless of the machine is 90-100 Psi.

Travel Speed

Your travel speed will depend on how thick the material is that you are cutting. The sparks should be coming out straight down on the other side of the plate when travelling at the correct speed.

If you’re cutting too fast, the sparks will spray at a very steep angle in the opposite direction than you’re cutting. Some sparks might even fly out from the top.

If they’re flying out of the top, it means your plasma arc isn’t cutting all the way through, and the sparks are bouncing off the part that is still joined together.

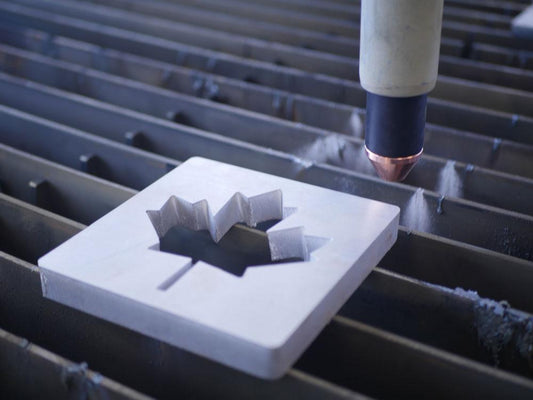

CNC Tables

CNC stands for Computer Numerical Control which means, you will get all the hard work done for you quick and automatically.

Premier plasma CNC Tables for example, are CNC tables with all the components you would need to get your job done quick and accurate. however, you can still add a router kit for CNC wood engraving and even add a rotary pipe cutter.

You do need to program what you want into a CNC computer, and there are specific programs, that need to be used for the computer to understand what kind of cuts you’re inputting. Some of the software you can use include sheetCAM, AutoDesk Fusion 360, MasterCAM and others.

These CNC tables usually work by connecting the plasma torch to an arm that can run back and forth (Y-axis) and left to right (X-axis) over the table to get the cut done quickly and accurately for you.