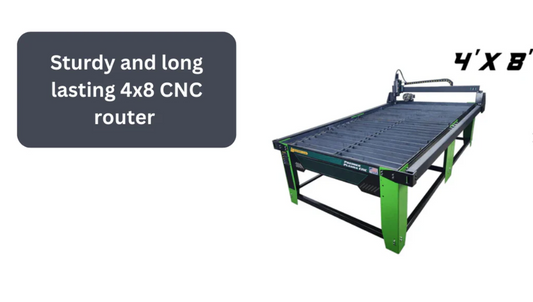

Exploring CNC Plasma Cutter Machine Applications in Metal Fabrication

Metal fabrication has always been a significant task in many industries. And in this work, it is quite difficult to ascertain speed as well as accuracy. But ever since CNC Plasma Cutter Machines came along, they have revolutionized the way we work with metals. If you're interested in metal fabrication or just love working with metals, you definitely know how excellent CNC plasma cutters are. These are synonymous with precision cuts, accuracy, speed, and versatility.

What is a CNC Plasma Cutter Machine and How does it work?

A CNC plasma cutter (computer numerical control) uses a hot jet of ionized gas (plasma) to cut the metals. This CNC feature allows for precise control of the cutting process, driven by computer-generated designs. This means the computer has full control of the motion of the torch and electrode. This combination of CNC technology and plasma cutting brings highly accurate metal cutting designs.

Key Applications of CNC Plasma Cutter Machine in Metal Fabrication

Industrial Manufacturing

CNC plasma cutters are widely used in industrial manufacturing for cutting metal sheets and plates. They help in creating parts for automotive components, machinery parts, and other industrial projects. This helps in large-scale production and reduces labor costs and time simultaneously.

Artistic Metalwork

CNC plasma cutter machines are known for precision machining, and this allows artists and designers to create complex designs out of metal. So that unique signage, metal art, detailed metal sculptures, and other decorative pieces can be created. Artists love the ability of plasma cutters to transform digital designs into tangible metal pieces with precision.

Construction and Architectural

When it comes to construction and architectural projects, CNC plasma cutters are used to produce metal components that require precise measurements and cuts. This includes structural beams, brackets, and custom metal parts for buildings and infrastructure. The accuracy of CNC plasma cutters ensures that components fit perfectly and enhance the aesthetic appeal of construction projects.

Medical Devices

Whether it's modern surgical equipment or custom orthopedic implants, the CNC plasma cutter machines do all this with full precision. CNC machine's capabilities have reshaped modern medicine's landscape. Their ability to create patient-specific components could pave the way for personalized medicine. This helps healthcare professionals to provide tailored solutions that significantly improve patient outcomes and overall quality of care.

Aerospace and Automotive Industries

CNC plasma cutter machines play a crucial role in Aerospace and Automotive industries due to their exceptional precision cuts. They used to cut complex design engine parts, strong airframe structures, body panels, etc. In aerospace, the precision of a CNC machine is crucial for producing parts that meet strict safety and performance standards.

Repair and Maintenance

You may be surprised but CNC plasma cutters are also great for repair and maintenance tasks. They used to join the parts and cut out the broken or damaged parts from metal structures. They also create replacement parts quickly. This is especially helpful in industries such as pipeline repair, shipbuilding, and heavy equipment maintenance where downtime must be kept to a minimum.

Advantages of Using CNC Plasma Cutter Machines

Here are 4 renowned advantages of CNC plasma cutting machines. Let’s have a look at:

- Precision and Accuracy: The CNC (computer numerical control) ensures precise cuts with minimal human error, which is necessary for producing high-quality parts.

- Speed and Efficiency: Compared to conventional cutting techniques, plasma cutting is substantially faster.

- Versatility: CNC plasma cutter machines can handle multiple metals and thicknesses, making them suitable for various applications.

- Cost-Effective: By reducing material waste and labor costs, CNC plasma cutting machines ultimately become cost-effective equipment for metal fabrication.

Embed it: https://premierplasmacnc.com/blogs/news/how-cnc-plasma-table-takes-metalworking-to-the-next-level

Final Thoughts

In the modern era, CNC plasma cutter machines are a perfect example that shows how modern technology has transformed the traditional metal fabrication process. They offer unmatched precision, speed, and versatility. Businesses and hobbyists can leverage the full potential of these machines for precision machining across various applications.

If you are a manufacturer or an artist who wants to improve productivity and create intricate metal designs respectively, you should invest in a CNC plasma cutter. This machine is a way that leads to a world of possibilities for you.

Kindly visit Premier Plasma - an ultimate shop for high-quality CNC Plasma Cutter Machines at competitive prices to provide customers with opportunities to grow their CNC business. So, let’s grow together!